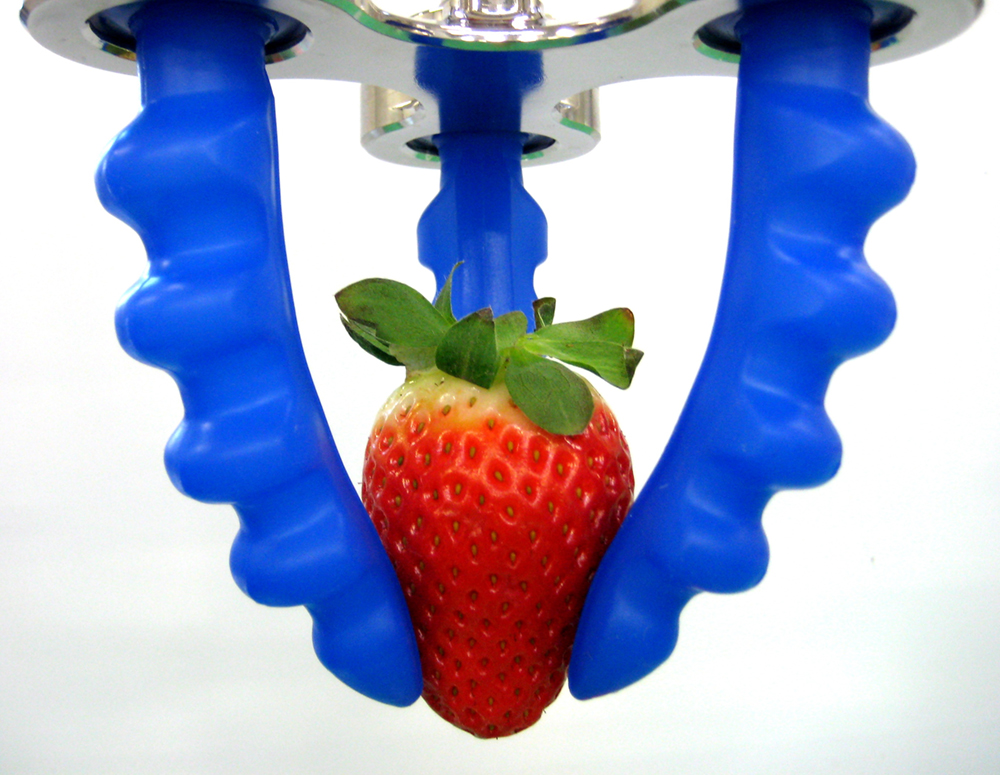

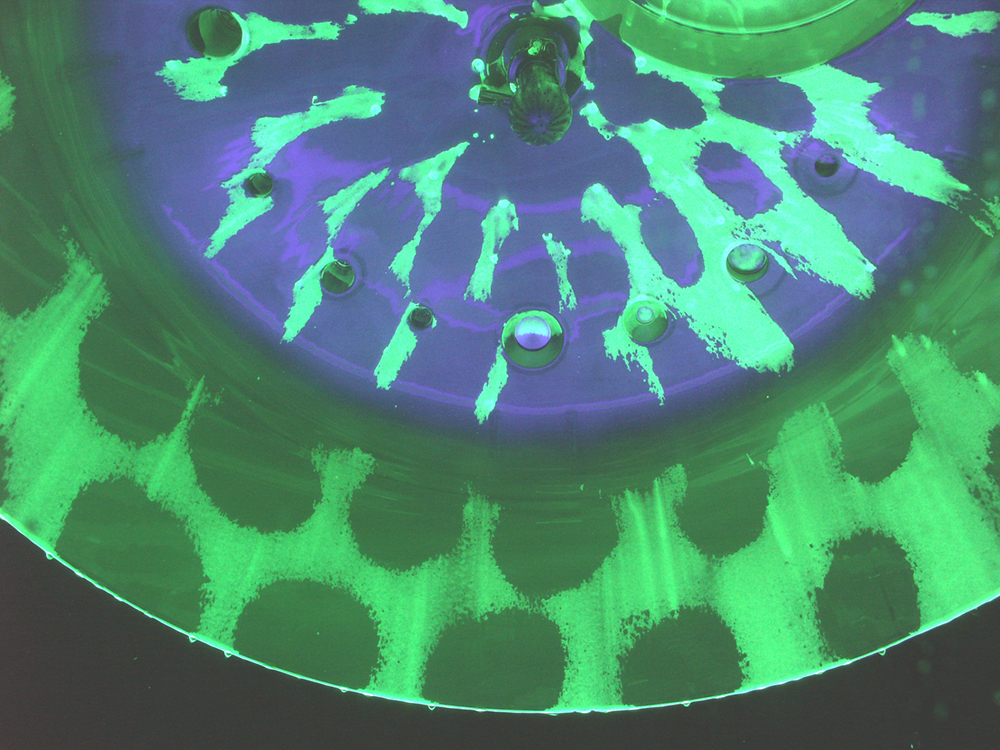

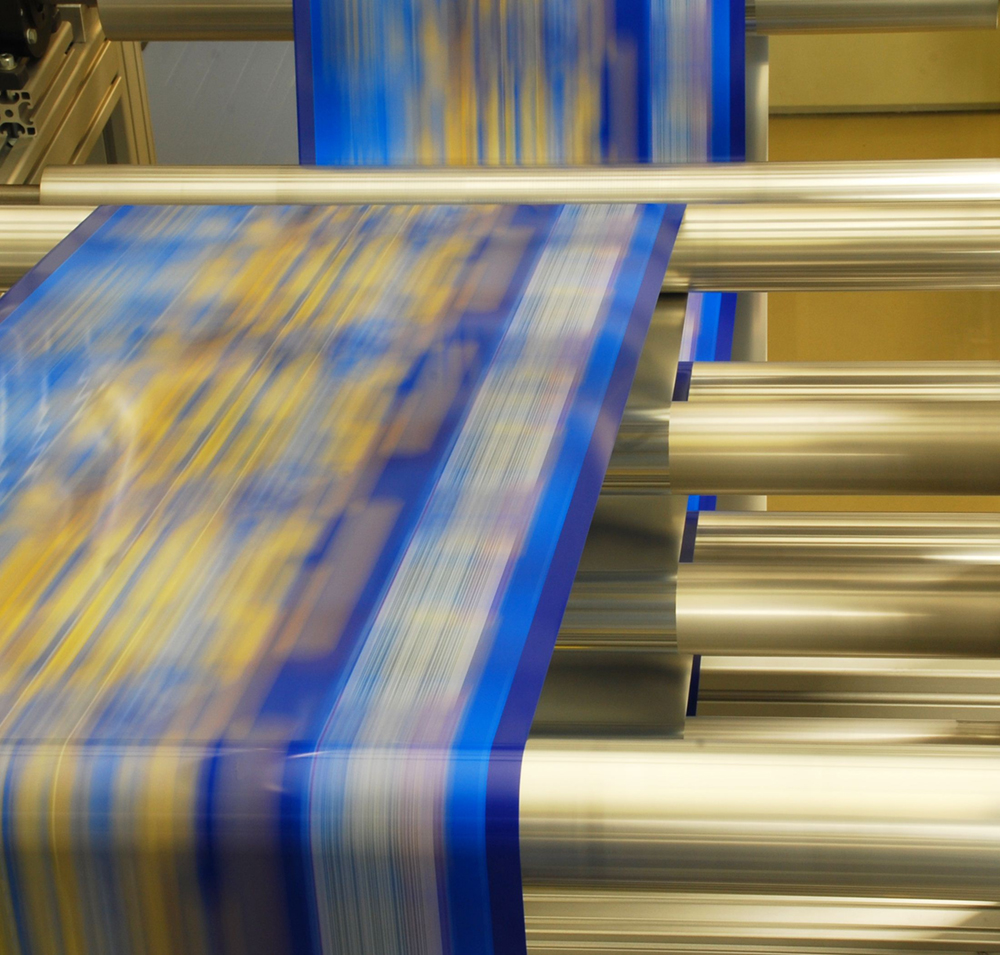

Adaptable processes

The components of adaptable processes adapt to changing properties of natural and synthetic materials and to changing process conditions, so guaranteeing higher process stability. Due to automated processing they can be used for a wide range of goods and can be integrated into adaptable value creation chains.

At the Fraunhofer IVV Dresden we put emphasis on an optimal balance between efficiency and adaptability and effective technical implementation in order to reach the following goals:

- The manufacture of specific products

- Measurement of fluctuating process and product properties

- Adaptation of processes to fluctuating properties in order to ensure constant product properties

- Analysis of process data to improve efficiency

- Development of self-learning assistance systems to aid human-machine interactionResearch projects „Adaptable processing methods“

Fraunhofer Dresden

Fraunhofer Dresden