Spatial Light Modulators

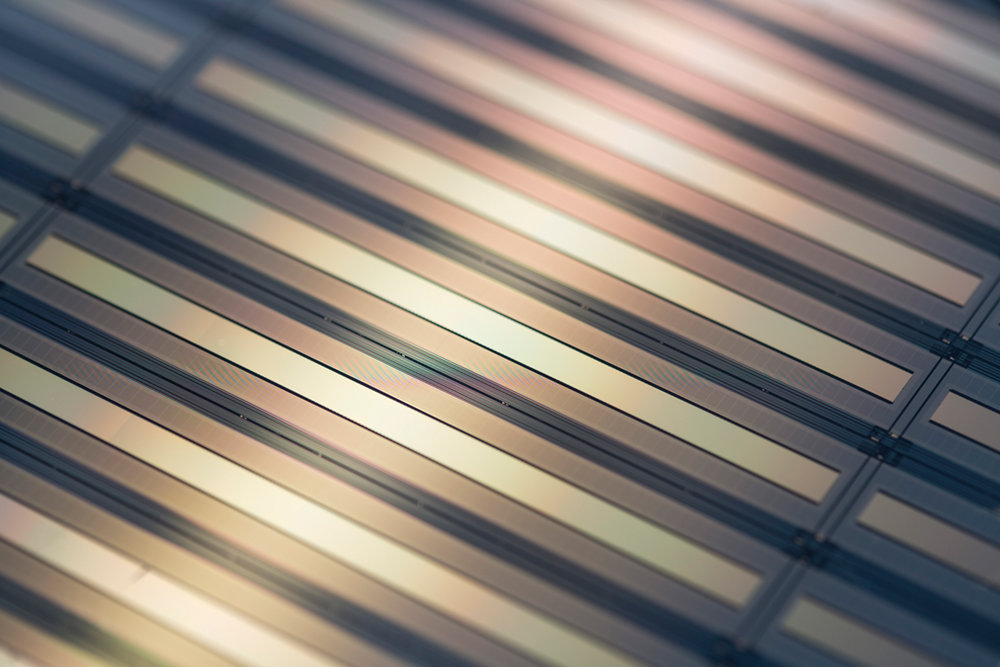

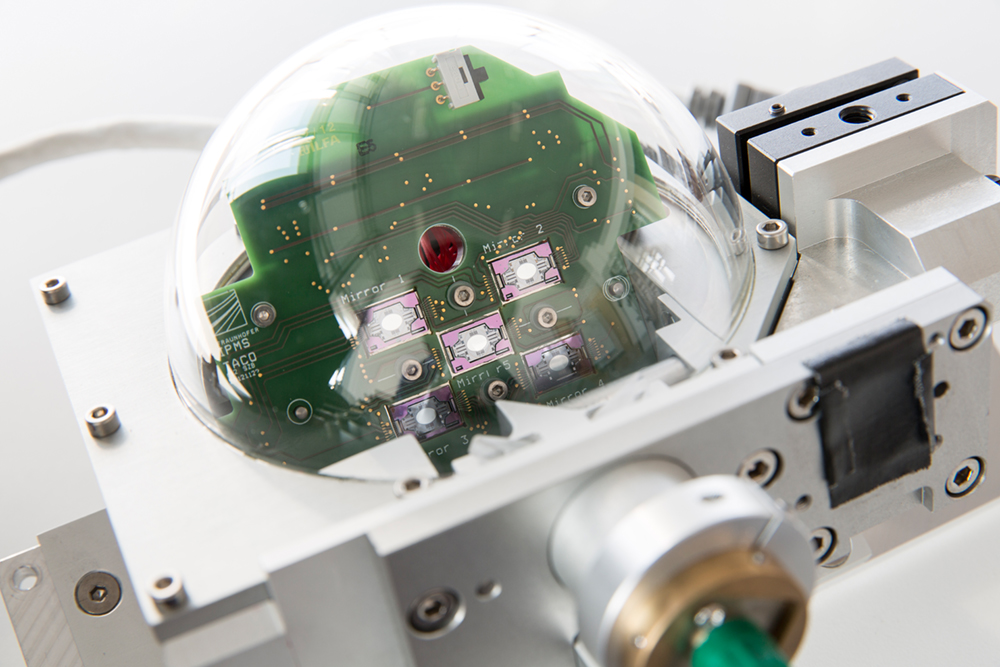

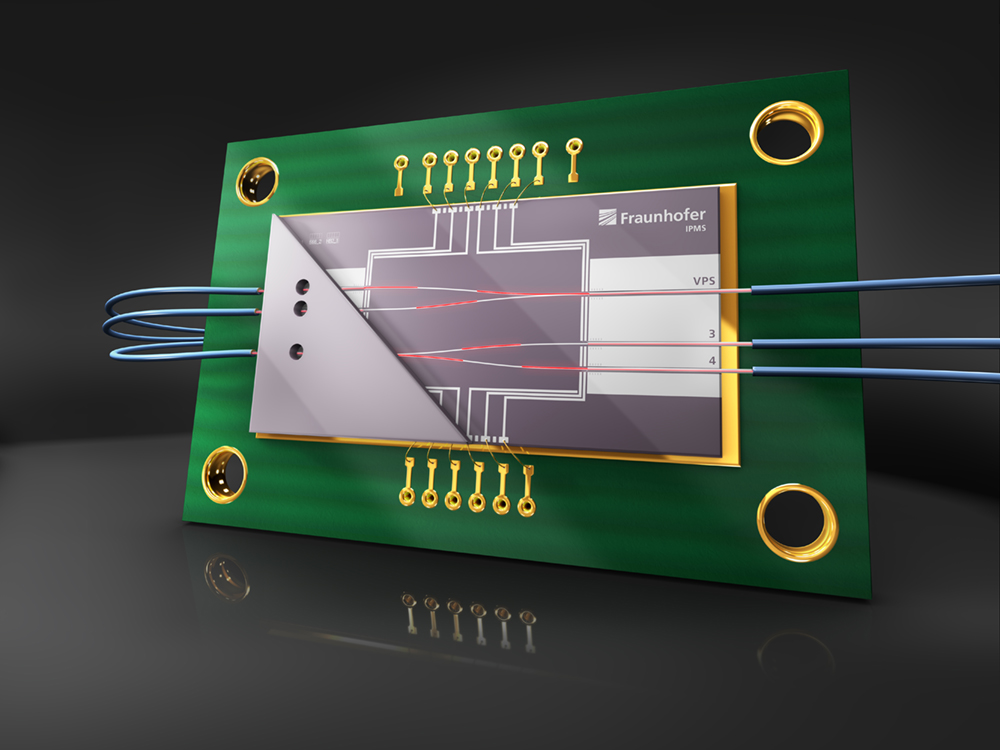

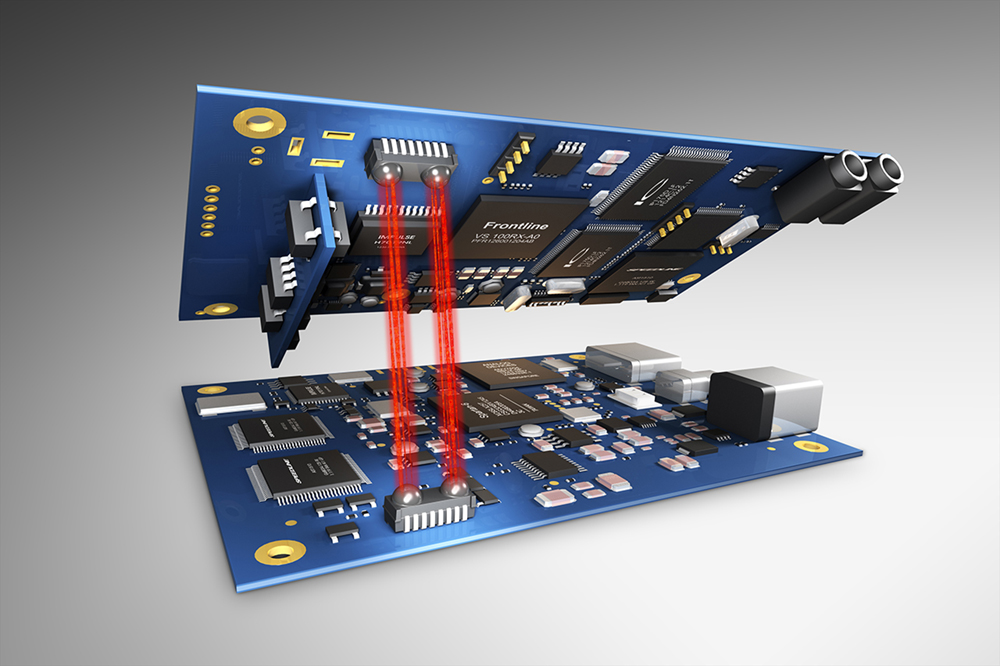

The spatial light modulators developed at Fraunhofer IPMS consist of arrays of micromirrors on semiconductor chips, whereby the number of mirrors varies depending on the application, from a few hundred to several millions. In most cases this requires a highly integrated application-specific electronic circuit (ASIC) as basis for the component architecture in order to enable an individual analog deflection of each micromirror. In addition, Fraunhofer IPMS develops electronics and software for mirror array control.

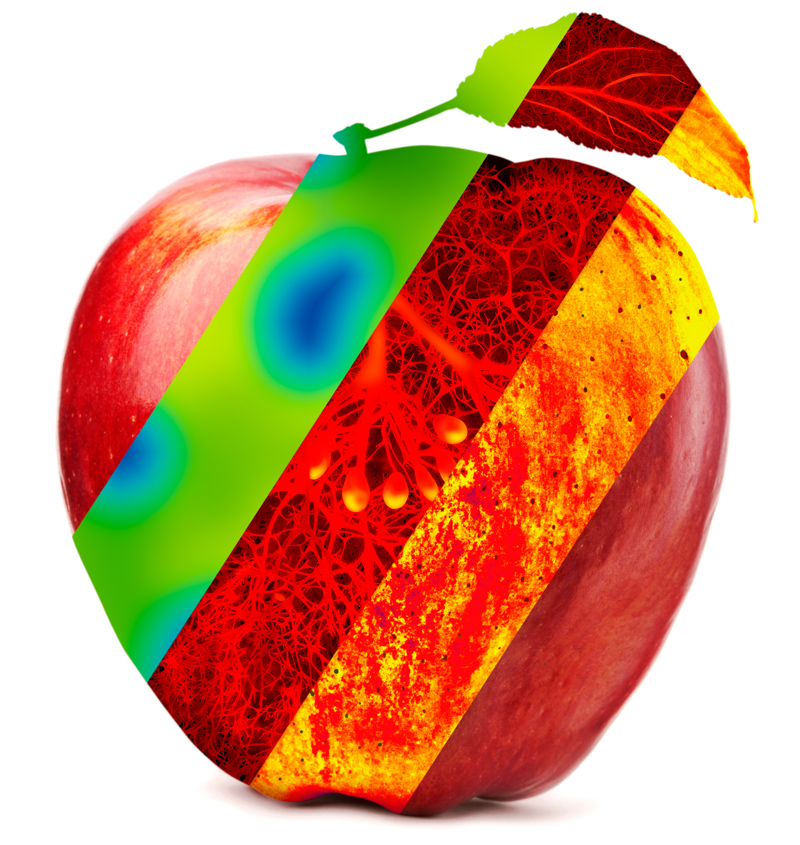

The individual mirrors that vary in number and size per chip can be tilted or vertically deflected depending on the application, so that a surface pattern is created, for example to project defined structures. High-resolution tilting mirror arrays with up to 2.2 million individual mirrors are used by our customers as highly dynamic programmable masks for optical micro-lithography in the ultraviolet spectral range. The mirror dimensions are 10 μm or larger. By tilting the micromirrors, structural information is transferred to a high-resolution photo resist at high frame rates. Further fields of application are mask inspection and measurement technology for the semiconductor industry, microscopy and prospectively laser printing, marking and material processing.

Piston micromirror arrays can for example be used for wavefront control in adaptive optical systems. These systems can correct wavefront disturbances in broad spectral ranges and thereby improve image quality. The component capabilities attract special interest in the fields of ophthalmology, astronomy and microscopy, as well as in spatial and temporal laser beam and pulse shaping.

Fraunhofer Dresden

Fraunhofer Dresden